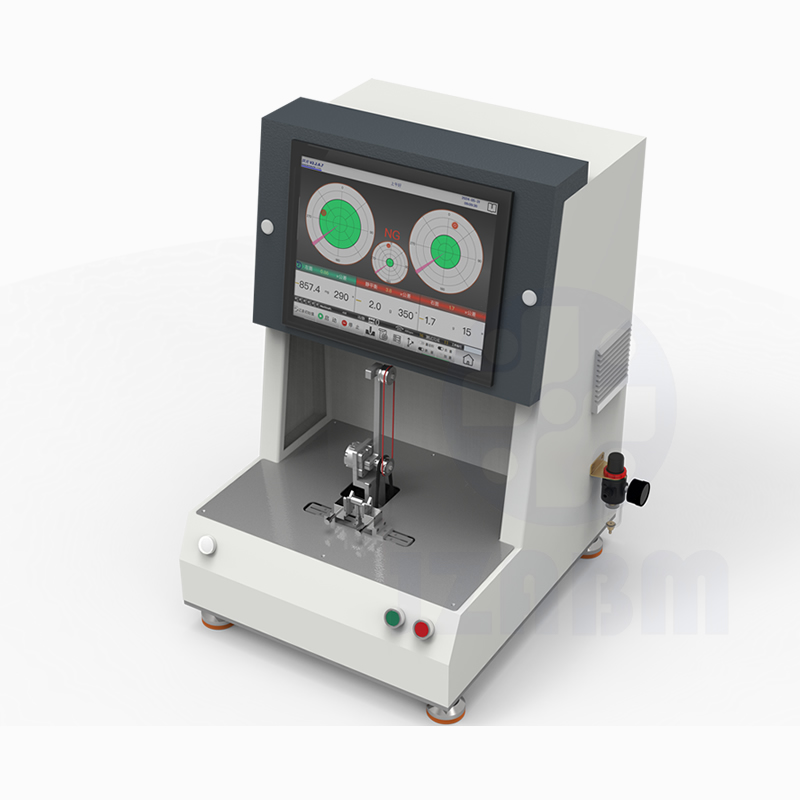

РЛД-01 Vertical Balancing Machine is primarily suitable for small, disc-type (rotor-type) workpieces that require high-precision dynamic balancing detection.

workpiece mass: 20-1000g; maximum outer diameter: 280миллиметр, its typical applicable workpiece types include:

-

Motor Rotors: Small fan motors, stepper motor rotors, servo motor rotors, and rotors for power tools (например., power drills, angle grinders).

-

Automotive Components: Turbocharger rotors, small water pump rotors, brake system components, clutch plates.

-

Ventilation and Refrigeration Equipment Parts: Small centrifugal impellers, CPU cooling fans, indoor air conditioner fan wheels.

-

Household Appliance Parts: Washing machine drain pump impellers, vacuum cleaner motor blades, blade assemblies for food processors (например., juicers, blenders).

-

Mechanical Transmission Parts: Pulleys, couplings, small gears, Маховики.

Функции

I. Basic Configuration

-

Display: 15-inch industrial integrated computer.

-

Vibration monitoring sensor: High-precision velocity sensor.

-

Speed measurement sensor: Laser sensor or proximity switch.

-

24V power supply: Mean Well power supply.

-

Drive motor: Мицубиси.

-

Fixture: Expanding sleeve (pneumatic).

II. Testing Process

-

The operator places the workpiece on the test fixture, powers it on, and presses the start button.

-

The fixture clamps the workpiece, accelerates it to the balancing test speed, and begins balance measurement.

-

After balance measurement is completed, the screen displays the unbalance amount and angle of the workpiece. The servo motor automatically stops the workpiece at the position requiring correction. A pass result is displayed in green, while a fail result is shown in red.

III. Testing Performance and Specifications

-

Balance measurement accuracy: Minimum achievable up to 0.1 гмм/кг.

-

Balance testing time: Approximately 10 товары второго сорта.

-

Workpiece mass range: 20–1000 g.

-

Workpiece outer diameter: 10- 280 миллиметр.

Балансировочные станки JZABM

Балансировочные станки JZABM